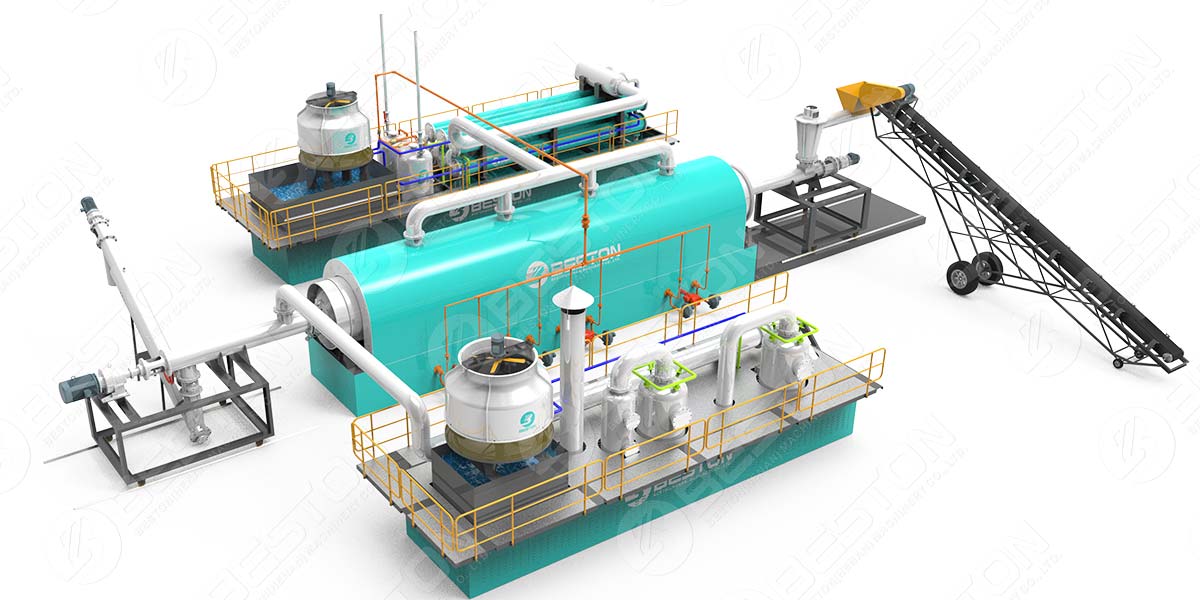

Continuous tyre pyrolysis plants are used to process waste tyre into carbon black and fuel oil. These plants typically include a pretreatment system, a continuous pyrolysis plant along with a continuous discharge and feeding system controlled by a PLC system. The primary part of these plants is the pyrolysis system.

Since the feeding and the discharge system is continuous, this type of pyrolysis plant is able to work non-stop or round the clock which helps to save time and energy. At the same time, the PLC control system translates into far fewer labor costs.

Raw Materials

The raw materials used in a continuous waste tyre pyrolysis plant include a variety of different waste tyres derived from commercial and industrial sectors. The most common waste materials include motorcycle tyres, bicycle tyres, OTR tyres, inner tubes, rubber overshoes, rubber hoses, truck tyres, car tyres, and more.

Working Process

To maintain ongoing feeding and discharging, the waste tyres have to be small in size. So before the pyrolysis process can commence, the materials are first shredded into smaller and more manageable pieces. Here are more details associated with this pyrolysis machine for sale process:

– Collect Waste Tyres

Waste tyres are available in many shapes and sizes from large OTR tyres to smaller car tyres.

– Shred Tyres

A specialized shredder is used to process the tyres into 3 to 5cm pieces. This system is a fully automatic shredder that connects directly to the feeder. This step does away with having to transfer the materials into the reactor.

Through a sealed unique feed-system, the broken down tyres are then fed directly into a pyrolysis reactor which achieves a sustainable feeding process. Get pyrolysis plant cost here.

– Heating And Continous Pyrolysis Process

The pyrolysis reactor is heated by natural gas, LPG, or fuel oil. During these heating processes, the reactor rotates 360 degrees, to ensure the tyre waste is uniformly heated. Once the temperature reaches around 300℃, the tyres crack and break down into oil gas.

– Cooling

The oil gas then flows into a 3-stage condensing system, where the gas cools down. The liquid oil produced through this process is then collected and stored in an oil tank. The leftover non-condensable gas is then used to heat the pyrolysis reactor or stored.

– Discharge

Carbon black is also produced in this process. This product is discharged via a slag-discharge system. This system is sealed, making it environmentally friendly.

Final Products Of The Continuous Tyre Pyrolysis Plant

– Pyrolysis Oil

The pyrolysis oil is either sold directly or reprocessed into gasoline and diesel via waste-oil distillation equipment. Pyrolysis oil is also useful as an industrial fuel material for burning.

– Carbon Black

Carbon black is also sold directly or reprocessed into high-quality carbon via a carbon-black processing machine. Carbon black is also used to produce carbon bricks.

– Steel Wire

Steel wire extracted from the waste tyres are used to make iron or steel rods or reprocessed for other uses.

– Combustible Gas

The combustible gas produced through the tyre pyrolysis plant is recycled and then used as fuel to carry on providing a source of heat to the reactor.