In a world where environmental consciousness is on the rise, innovative technologies like continuous pyrolysis plants are gaining increasing significance. These remarkable machines are at the forefront of converting waste materials into valuable resources, offering both economic benefits and environmental solutions.

Understanding Continuous Pyrolysis Plant

Continuous pyrolysis plant is cutting-edge recycling systems designed to efficiently and sustainably convert various types of organic and waste materials into valuable end products, such as biofuels, biochar, and syngas. Unlike batch pyrolysis plants, continuous systems operate continuously, ensuring a seamless production process with minimal downtime. This feature makes them particularly suitable for large-scale operations and industries seeking eco-friendly alternatives to traditional waste disposal methods.

The Pyrolysis Process

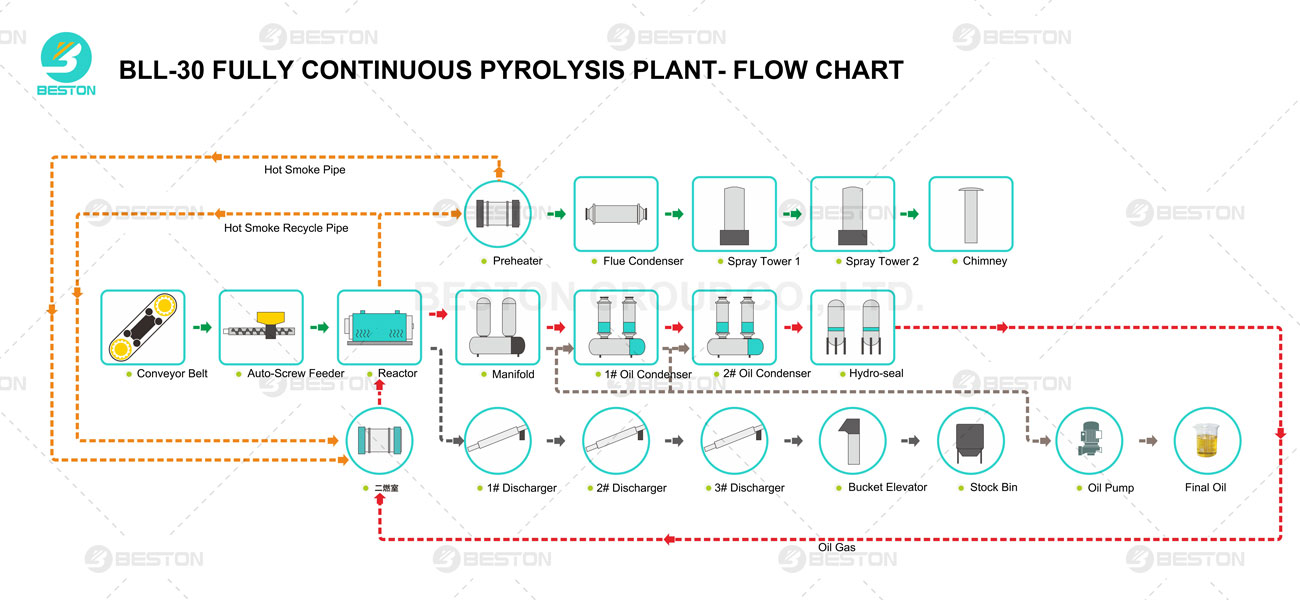

At the heart of continuous pyrolysis plants lies the pyrolysis process, a thermochemical decomposition method that occurs in the absence of oxygen. This unique process allows organic materials to break down into valuable byproducts through heat-induced chemical reactions. The primary components of this process are:

- Feeding System: Organic or waste materials, such as plastics, rubber, biomass, and municipal solid waste, are continuously fed into the pyrolysis reactor.

- Pyrolysis Reactor: Inside the reactor, the materials are subjected to high temperatures, typically ranging from 400°C to 600°C, without oxygen. This absence of oxygen prevents combustion and ensures the materials undergo pyrolysis.

- Vapors and Gases: As the materials heat up, they release vaporized gases containing valuable components such as bio-oil, syngas, and biochar.

- Condensation: These vapors and gases are then condensed into their liquid or gaseous forms, ready for collection and utilization.

- Residue Collection: The solid residues left behind in the tyre/plastic pyrolysis plant, such as carbon black or ash, can be collected and used in various applications.

Applications of Continuous Pyrolysis Plant

The versatility of continuous pyrolysis plants extends to a wide range of applications, making them indispensable in multiple industries:

1. Waste Management

Continuous pyrolysis plants offer a sustainable solution to tackle the global waste crisis. They can process various types of waste materials, including plastics, tires, rubber, and municipal solid waste, reducing landfill usage and minimizing environmental pollution.

2. Energy Production

Biofuels and syngas produced by continuous pyrolysis plants serve as eco-friendly alternatives to conventional fossil fuels. These can power industrial machinery, generate electricity, or even fuel vehicles, contributing to a greener energy landscape.

3. Agriculture and Soil Improvement

Biochar, a valuable byproduct of the pyrolysis process, enhances soil quality and promotes crop growth. Continuous pyrolysis plants can supply a consistent source of biochar to agriculture, reducing the need for chemical fertilizers.

4. Environmental Remediation

The ability to convert contaminated waste materials into useful resources makes continuous plastic/tyre to oil plant effective tools for cleaning up polluted sites and addressing environmental issues.

The Advantages of Continuous Pyrolysis Plant

Investing in continuous pyrolysis plants brings forth a multitude of advantages:

1. Sustainable Resource Management

These plants significantly reduce waste volume, helping to manage waste streams more sustainably.

2. Lower Carbon Footprint

By producing cleaner biofuels and mitigating the release of harmful greenhouse gases, continuous pyrolysis plants contribute to a reduction in carbon emissions.

3. Economic Viability

The sale of valuable end products, such as biofuels and biochar, can generate substantial revenue, potentially resulting in a quick return on investment.

4. Environmental Protection

Continuous pyrolysis plants offer an environmentally friendly solution to waste management and pollution control, supporting global efforts to combat climate change.

Future Prospects

As technology continues to advance, continuous pyrolysis plants are poised for even greater contributions to sustainability. Ongoing research and development aim to improve efficiency, broaden the range of materials that can be processed, and enhance the quality of end products. These innovations promise a brighter future where waste is seen as a valuable resource rather than a burden. We Beston Group welcome any questions you may have about the pyrolysis project