In our ever-evolving quest for sustainable solutions to combat plastic pollution and harness valuable resources, the plastic to oil machine emerges as a technological marvel. This ingenious piece of equipment holds the promise of turning plastic waste, often considered an environmental menace, into a valuable commodity – liquid gold, or more accurately, liquid fuel. In this comprehensive exploration, we will delve into the intricate workings of the plastic to oil machine, its environmental implications, and its role in reshaping the future of waste management.

Decoding the Plastic to Oil Machine

Before we dive into the mechanics of this revolutionary device, let’s gain a fundamental understanding of its core function. The plastic to oil machine operates on the principles of pyrolysis, a thermal decomposition process that takes place in the absence of oxygen. Pyrolysis is the transformation of organic materials into valuable products through the application of heat. In this case, plastic waste serves as the raw material.

Here’s a simplified breakdown of the process:

- Feedstock Input: Plastic waste, which can range from discarded packaging materials to non-recyclable plastics, is loaded into the machine.

- Heating: The plastic is subjected to high temperatures within a controlled environment, without oxygen. This triggers the pyrolysis process.

- Pyrolysis: During pyrolysis, the plastic waste undergoes thermal decomposition, breaking down into gas, liquid, and solid byproducts.

- Product Collection: The resulting products, primarily liquid oil, are collected and further refined for various applications.

The Environmental Implications

The significance of the plastic to oil machine extends far beyond its technical prowess. It addresses several critical environmental concerns:

- Plastic Waste Reduction: By converting plastic waste into valuable oil, these plastic pyrolysis plants contribute to reducing the volume of plastics that end up in landfills and our oceans.

- Energy Recovery: The liquid oil produced through pyrolysis can be used as an energy source, potentially reducing our dependence on fossil fuels.

- Resource Conservation: Pyrolysis technology promotes resource efficiency by extracting value from discarded plastics.

- Emissions Mitigation: Compared to traditional incineration, pyrolysis generates fewer harmful emissions, making it a more environmentally friendly option.

The Pyrolysis Process

Pyrolysis, the heart of the plastic to oil machine, involves intricate chemical reactions:

- Depolymerization: The long chains of polymers in plastics are broken down into smaller hydrocarbon molecules.

- Vaporization: Heat causes the plastic to vaporize, forming a gaseous mixture of hydrocarbons.

- Condensation: The hot gases are condensed into liquid oil, while any remaining solid residue can be further processed into char or used in construction materials.

Applications of the Liquid Gold

The liquid oil produced by the plastic to oil machine has a variety of applications:

- Fuel Production: The oil can be refined and processed into fuel, which can power industrial machinery or vehicles.

- Heating and Electricity Generation: It can be used as a heating fuel or to generate electricity.

- Chemical Feedstock: The liquid oil serves as a valuable feedstock in the chemical industry for producing various products.

- Asphalt and Construction: It finds use in road construction and as a binding agent in construction materials. Check the thermal desorption unit here.

Economic Viability

While the technology behind the plastic to oil machine is cutting-edge, its economic viability is a crucial consideration:

- Resource Value: The ability to convert plastic waste into a valuable resource is an attractive proposition.

- Energy Generation: The liquid oil can offset energy costs or be sold as a valuable energy source.

- Environmental Compliance: Businesses and industries seeking to meet sustainability targets may find these machines indispensable.

Challenges and Innovations

It’s worth noting that the plastic to oil machine is not without challenges:

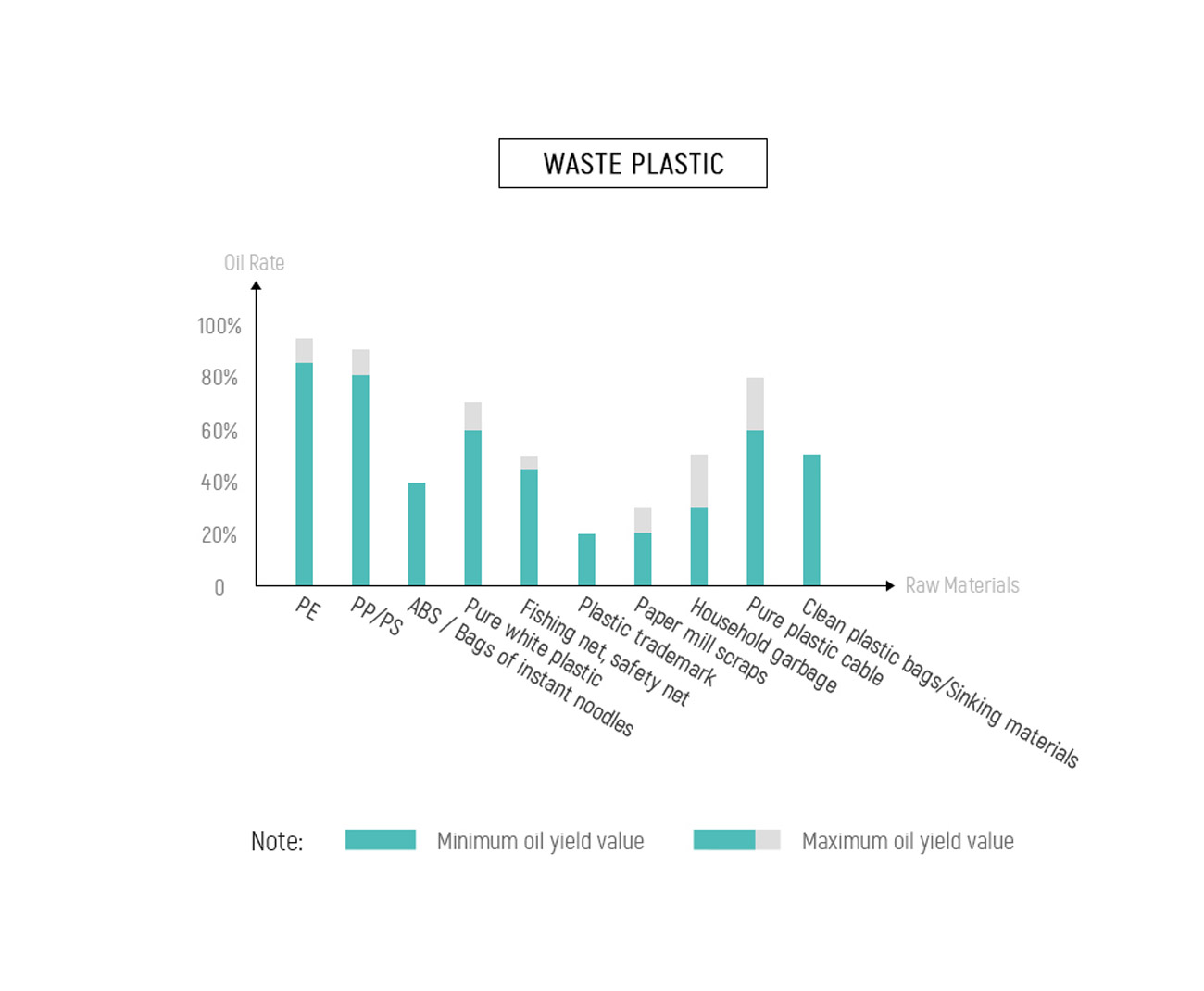

- Feedstock Quality: The quality and composition of the plastic feedstock can impact the efficiency and quality of the oil produced.

- Technology Optimization: Continuous research and development are essential to enhance the efficiency and environmental performance of these machines.

- Market Dynamics: The economic viability of producing oil from plastic waste is influenced by market conditions and the demand for alternative fuels.

Despite these challenges, ongoing innovations and advancements in pyrolysis technology are steadily overcoming hurdles and expanding the potential of the plastic to oil machine.

A Sustainable Future

In the battle against plastic pollution and the quest for sustainable energy sources, the plastic to oil machine stands as a testament to human ingenuity. It embodies the convergence of technology, environmental responsibility, and economic viability. As we move forward, the role of these machines in reshaping waste management and resource utilization cannot be overstated. They represent a tangible pathway toward a more sustainable and environmentally conscious future, where plastics are no longer seen as a menace but as a valuable source of liquid gold. More information from Beston Group.