Top manufacturers in the solid waste sorting machine industry (maquina clasificadora de basura) have become popular in both domestic and foreign markets. The lastest machines use advanced technology to separate garbage into various different material categories with excellent accuracy and efficiency. Some of the countries that customers live in include Norway, South Korea, Malaysia, Indonesia, South Africa, Hungry, and the Philippines.

The truth is that cities all around the world are having to find ways to deal with growing quantities of urban waste. It’s clear that landfill and incineration disposal methods are harmful to the natural environment, so cities are looking for the best ways to sort and recycle garbage.

Benefits

A top-rated garbage sorter is capable of processing waste items whose diameters exceed 40cm, such as furniture, branches, organisms, sand, branches, and more. Here are some of the advantages of a trash sorting machine from a globally-renowned manufacturer:

1. Automated operation. The machine has a fully automatic operating system, which means that it does not require a large workforce for operation. Waste treatment facility owners can save a fortune on labor costs with such a machine.

2. High sorting rate. The machine is able to achieve an accuracy sorting rate exceeding 90%. This means that very few recyclable materials end up being disposed of rather than processed into usable products.

3. Safe environment for workers. The machine designed by Beston (Henan) Machinery Co. ltd. has an advanced odor control system, which removes all toxic smells from the facility. Not only do the employees in the facility enjoy a more pleasant working, but the machine also does not pollute the surrounding natural environment with unpleasant smells.

Materials

The end products from a waste municipal garbage sorting plant include inorganic matter, irrecoverable fuel, organic matter, sand, ferromagnetic materials, and plastic. The end products have a wide range of profitable applications. The separated plastic waste can be converted into fuel oil via a plastic pyrolysis machine. That fuel oil can be easily sold in its unrefined state, or it can be refined further to extract higher profits from the international market.

Waste ferromagnetic materials can be sent to a metal factory for smelting to allow them to be reused. Meanwhile, stones and sand can be transformed into construction bricks from the building industry. Organic matter can be formulated into fertilizer or turned into valuable biogas via fermentation. Get more details about como separar los residuos solidos.

Machine Parts

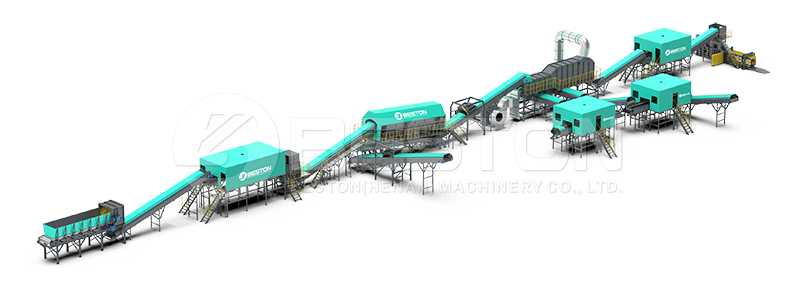

A garbage sorting machine is made up of many different modules, components, and parts, which each have different functions. Some of those components include plate feeder, rotating screening machine, deodorization tower, uniform feeder, and magnetic separator. A machine can be customized to the needs of solid waste sorting and treatment facility.

Comparing Machines

When it comes to comparing different waste separation machines, many different factors should be taken into account, including price, installation time, processing capacity, power consumption, working time, footprint size, and more. Premium models are capable of processing over 20 tons of waste an hour. The type of machine a MSW plant owner decides to invest in will generally depend on the type of waste they need to sort.