Biochar production equipment, such as Beston Machinery’s coconut shell charcoal making machine, is used to convert various types of biomass waste into profitable end products using carbonization and pyrolysis technologies. While biomass waste does not pose as much as a problem for the natural environment as non-biodegradable waste materials like rubber and plastics, it still needs to be processed by waste processing facilities – a biochar production equipment and turn it into profitable commodities.

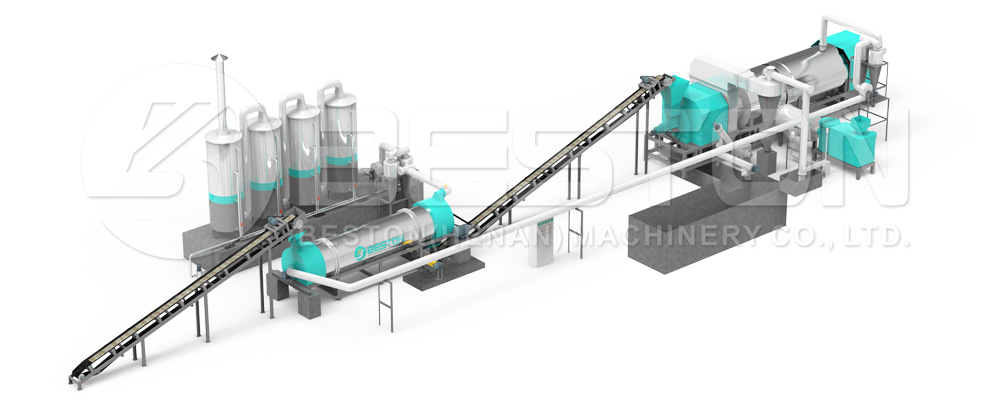

Beston Machinery Coconut Shell BioChar Machine

The great thing about coconut shell charcoal making machines from Beston is that they utilize “One Fire Two-Stage” double cylinder designs to ensure that heat from carbonization reactors is reutilized for the raw material drying process. One of the manufacturer’s most popular machine models is the BST-30. This model has an hourly feeding capacity of three tons and utilizes a continuous working method. To put this into perspective, the machine can theoretically be used to convert 72 tons of coconut shell waste into valuable commodities each day.

The BST-30’s furnace can be heated from a wide range of fuel sources including biomass, LPG, diesel, coal, natural gas, charcoal, wood, etc. The total power requirement is 72 kW/h and it employs a recycling water cooling design. Besides processing coconut shells, other types of biomass waste that the BST-30 machine can carbonize include bamboo, sawdust, straw, palm shells, etc. Click here to know more: https://bestonpyrolysisplant.com/.

• The moisture content of raw materials must be less than 50% to guarantee charcoal output with a high carbon percentage. Note: Charcoal with a carbon percentage exceeding 95% is more profitable as it has higher thermal value and produces less smoke when burnt.

• Coconut shells must be crushed into pieces less than 20mm in length.

• Access to high kilo calorie fuel to heat the reactor to required temperatures.

• The combustible gas output should be recycled through the plant to refuel the reactor and reduce running costs.

• The coconut shell charcoal making equipment must have advanced dedusting systems to ensure emissions meet EU standards.

Coconut Shell Charcoal Applications

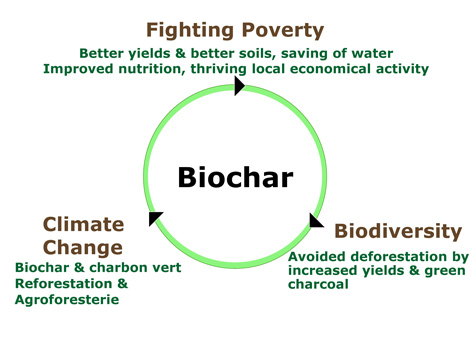

Coconut shell charcoal is a profitable commodity as it has a wide range of applications. It can be used as an industrial fuel source or to fuel outdoor barbeque grills. It can be milled into charcoal powder for exportation to the global market. Coconut shell charcoal can also be further process into active carbon. Active carbon is a sought-after material by the wastewater recycling industry. Biochar is also great for improving soil drainage properties or as a biological carbon fertilizer. It can be used to increase crop yields in the agriculture industry tenfold.

Biochar Production Equipment

In addition to investing in charcoal making machine, other pieces of equipment that biomass waste processing facilities might want to invest in include shredders, crushers, millers, grinders, spray towers, de-dusting systems, and much more. There are lots of pieces of machinery that can make a biomass waste to bio charcoal production line more efficient. Be sure to check out additional biochar production equipment for sale online. See the blog: http://bestonchina.weebly.com/.