Transport equipment, cars, trucks or others need rubber tyres for their smooth movement and these tend to get worn out after long use. The waste tyres were in earlier days put into landfills where they took a long time to decompose and led to environmental problems. It is now possible to use a fully continuous tyre pyrolysis plant to convert the waste tyres into oil, carbon black, and hydrocarbon gas, all byproducts that have a use. This can reduce waste in landfills and save the environment.

The Process of Pyrolysis

The process of pyrolysis chemically decomposes the organic materials in the tyre, mainly rubber, at very high temperatures and does so in the absence of oxygen and under pressure. These could be as high as 430°C (800°F). This changes the physical as well as the chemical composition of the waste tyres and is a process that cannot be reversed. Pyrolysis converts organic material into a residue that contains ash, carbon and smaller quantities of oil and gas. Click here to know more: https://bestonpyrolysisplant.com/.

The Makeup of a Pyrolysis Plant

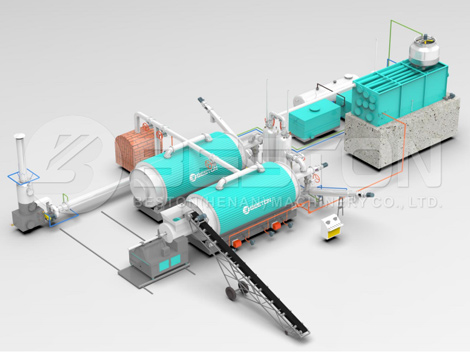

The main component of a pyrolysis plant is its reactor in which the waste tyres are heated using fuel, like wood, gas, or coal, among others. In this heating, oil gas is first produced and is required to be sent to a condenser that will liquefy the gas in to oil that has to go to a oil tank. The gas that is not condensed is led back into the reactor to act as fuel for burning. Once the reactor cools down carbon black is produced and needs to be removed. Steel, often used in radial tires will also be part of the residue after burning.

A pyrolysis plants can also be designed as a fully continuous tyre pyrolysis plant that produces the byproducts without any need for cooling the reactor.

A fully continuous tyre pyrolysis plant design allows all operations from the loading of the tyres to the production of the various byproducts to be carried out without any interruption. Such tire recycling plant can work all round the clock and throughout the year, as long as there is a continuous flow of raw material – waste tyres. It works like an assembly line that constantly takes in the raw product and produces a constant flow of oil, carbon black and steel.

For continuous feeding waste tyres need to be shredded and made into a smaller size. The tyres are fed into a shredding machine and cut to a size of about 2″. The shredding process also separates out the steel in the tyres and this can be retrieved magnetically from these shredders. The shredded material is automatically conveyed to the reactor, where heat is already being generated. The oil gas finds it way to connected condensers where it is converted into liquid oil that is then stored in tanks. Carbon black is produced at certain temperatures and automatically retrieved. Multiple reactors are used with an internal rotating system and heated with hot air that uses other fuel or the oil gas for heating.

These plants that work continuously are controlled by computers and can be programmed, for all operations from feeding, burning and byproduct retrieval of carbon black, fuel oi and steel. If you want to know the tyre shredding, see the page: https://bestonpyrolysisplant.com/tyre-shredding-machine/.