Charcoal production is a versatile and environmentally friendly way to convert biomass into a valuable resource. In this article, we explore various machines that are integral to the charcoal production process. These include the charcoal carbonization machine, charcoal briquette making machine and more. Each of these machines plays a crucial role in the sustainable production of charcoal, offering different applications and benefits.

Charcoal Carbonization Machine: Turn Biomass into Charcoal

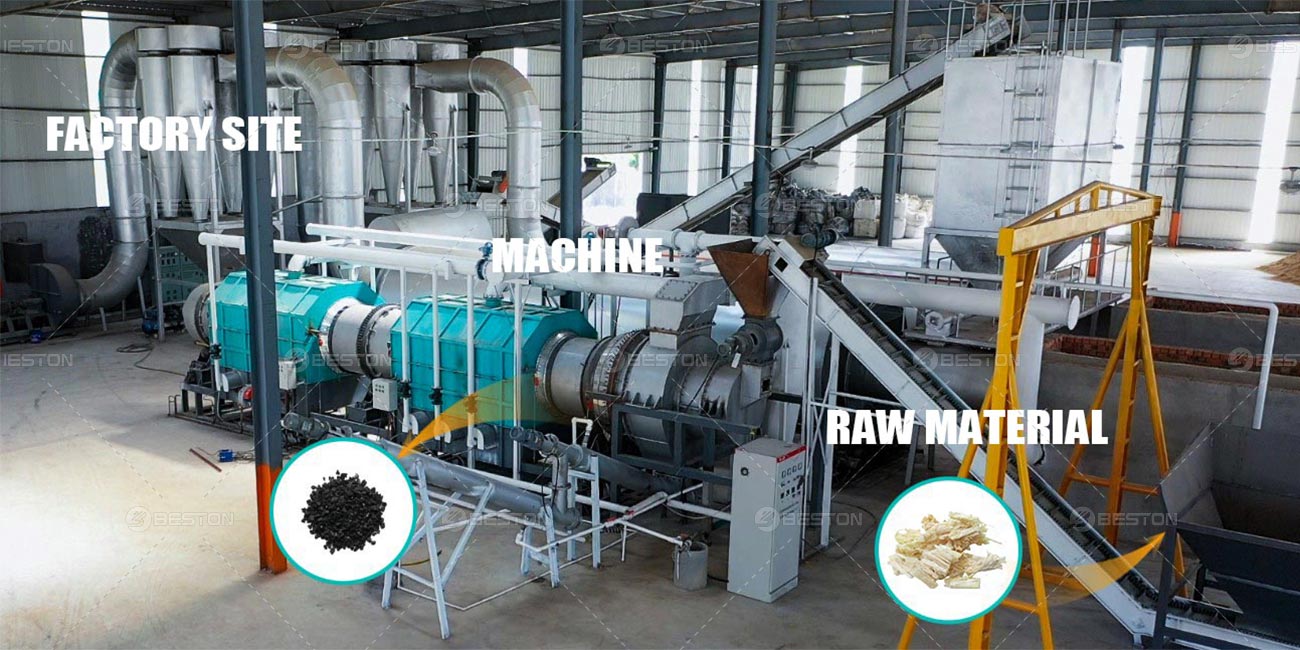

The charcoal carbonization machine is the cornerstone of biomass conversion. This equipment is designed to convert various forms of biomass, such as wood, coconut shells, and agricultural waste, into high-quality charcoal through the process of carbonization. During carbonization, the biomass is heated in an oxygen-limited environment, resulting in the decomposition of organic materials and the production of charcoal.

One of the key benefits of using a charcoal carbonization machine is its ability to produce charcoal with a high carbon content, which is highly sought after for both industrial and domestic uses. Moreover, the machine operates in an environmentally responsible manner by capturing and recycling the gases produced during carbonization, reducing emissions and contributing to a cleaner production process.

As industries and households increasingly seek sustainable alternatives, the demand for charcoal carbonization machines continues to grow, positioning this equipment as an essential investment for those involved in biomass processing and waste management.

Charcoal Briquette Making Machine: Turn Charcoal Powder into Briquettes

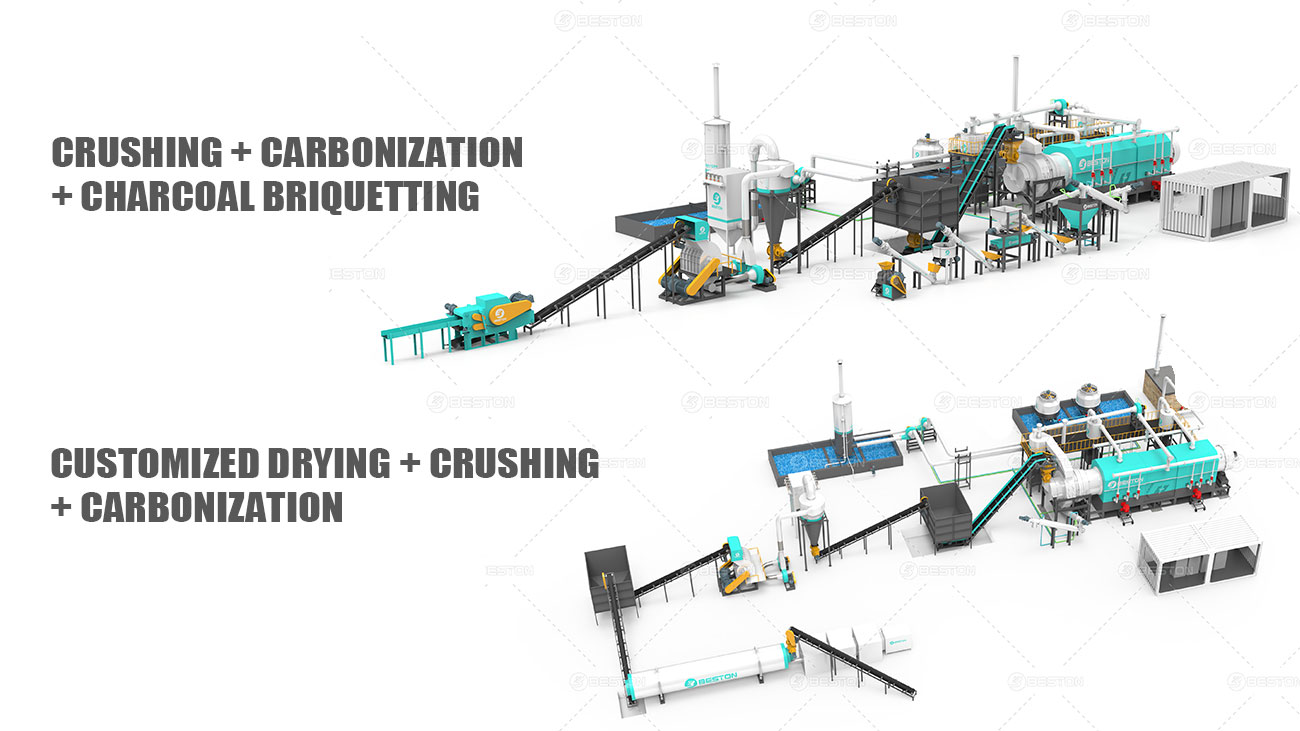

After producing charcoal through the carbonization process, the next step often involves transforming this charcoal into a more user-friendly form. This is where the charcoal briquette making machine comes into play. This machine compresses charcoal powder into uniform briquettes, which are easier to handle, store, and use compared to loose charcoal powder.

Briquettes made from charcoal powder are particularly popular in regions where they are used for cooking and heating. The uniform shape and size of the briquettes allow for consistent burning, making them an efficient and reliable fuel source. Additionally, briquettes have a higher energy density than raw biomass, offering a more concentrated and prolonged burn.

The charcoal briquette making machine is an essential component for businesses that want to maximize the value of their charcoal products. By turning charcoal powder into briquettes, companies can increase their product offerings and appeal to a broader market, further enhancing their profitability.

Shisha Charcoal Machine: An Application of Charcoal Carbonization Machine

The shisha charcoal machine is a specialized application of the charcoal carbonization machine, tailored for the production of shisha or hookah charcoal. Shisha charcoal is a unique product that requires specific characteristics, such as a slow burn rate, low ash production, and a pleasant aroma when burned.

To produce shisha charcoal, high-quality biomass charcoal is first produced using a charcoal carbonization machine. This charcoal is then processed using the shisha charcoal machine, which shapes it into the desired form, often small cubes or discs. The machine ensures that the shisha charcoal meets the stringent quality requirements needed for an optimal smoking experience.

Shisha charcoal is a premium product in many markets, particularly in the Middle East and North Africa. The ability to produce high-quality shisha charcoal can open up lucrative opportunities for manufacturers, allowing them to tap into this growing market.

Sugarcane Bagasse Charcoal Machine: An Application of Charcoal Carbonization Machine

Sugarcane bagasse, the fibrous residue left after extracting juice from sugarcane, is an abundant biomass resource with significant potential for charcoal production. The sugarcane bagasse charcoal machine is another application of the charcoal carbonization machine, specifically designed to handle this type of biomass.

Through carbonization, sugarcane bagasse can be transformed into high-quality charcoal, which can be used as a fuel source or for various industrial applications. The sugarcane bagasse charcoal machine efficiently converts this waste material into a valuable product, contributing to waste reduction and resource recovery in the sugar industry.

The use of sugarcane bagasse for charcoal production not only provides an additional revenue stream for sugar producers but also promotes sustainable practices by reducing the environmental impact of agricultural waste. As the world moves towards more sustainable practices, the sugarcane bagasse charcoal machine represents a forward-thinking solution for both waste management and energy production.

In conclusion, the integration of various charcoal production machines, from the charcoal carbonization machine to specialized equipment like the shisha charcoal machine and sugarcane bagasse charcoal machine, offers a comprehensive approach to biomass conversion. These technologies not only enhance the value of biomass resources but also contribute to sustainable development by promoting efficient and environmentally friendly production processes.