Pyrolysis has become a crucial technology in energy conversion and waste management. By thermally decomposing organic materials in the absence of oxygen, valuable products such as oils, gases, and char can be obtained. However, the molecular structure of feedstock significantly affects the pyrolysis pathways. This article explores the molecular-level differences in the pyrolysis of biomass, plastics, and waste tires.

Mechanisms of Biomass Pyrolysis

Biomass mainly consists of cellulose, hemicellulose, and lignin. Its molecular structure is rich in hydroxyl and ether groups, which influence its thermal decomposition. During pyrolysis, dehydration occurs first, followed by chain cleavage. Cellulose chains break at relatively low temperatures, producing small sugar-like molecules and volatile compounds. Lignin, with its complex aromatic structure, decomposes at higher temperatures, generating more aromatic hydrocarbons. The high oxygen content of biomass also leads to significant water release during pyrolysis.

Pyrolysis Characteristics of Plastics

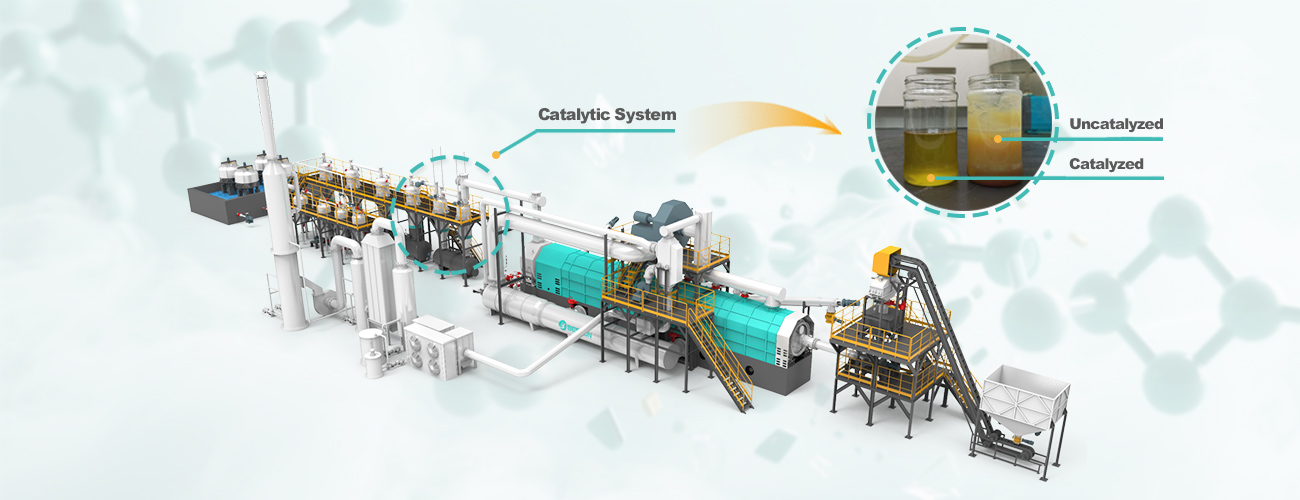

Plastics are long-chain polymers such as polyethylene, polypropylene, and polystyrene. Unlike biomass, they lack oxygen-rich functional groups. Their pyrolysis primarily involves chain scission and free radical reactions, generating short-chain hydrocarbons and liquid fuels. Due to the uniformity of polymer chains, the product distribution is relatively simple, and the required pyrolysis temperature is higher. In industrial applications, many facilities use waste plastic pyrolysis plant systems to convert waste plastics into usable fuel and chemical feedstocks.

Molecular Features of Waste Tire Pyrolysis

Waste tires consist of natural rubber, synthetic rubber, carbon black, and various additives. Their molecular structure contains unsaturated double bonds and crosslinked sulfur bridges, leading to both chain scission and sulfur decomposition during pyrolysis. The resulting products are complex, including oil, char, steel wires, and combustible gases. The crosslinked structure increases decomposition temperature and reaction time. Specialized waste tire pyrolysis plant equipment allows precise temperature and residence time control, maximizing yield and product quality.

Impact of Molecular Differences on Products

At the molecular level, biomass, plastics, and waste tires differ in chain structure, functional groups, and crosslink density. Biomass, with high oxygen content, forms acidic products and water. Plastics produce mainly liquid hydrocarbons due to uniform chains. Waste tires yield a diverse mix due to crosslinking, requiring separation processes. Understanding these differences helps optimize pyrolysis processes, increase oil and gas recovery, and reduce unwanted byproducts.

Industrial Applications and Technology Choices

In practice, selecting the right pyrolysis equipment and process parameters is critical. For waste plastics and tires, companies often rely on Beston Group for complete pyrolysis solutions, ensuring safety and product quality. Biomass pyrolysis focuses more on temperature gradients and gas management to avoid excessive char formation.

Future Trends

With increasing environmental concerns and renewable energy demand, the pyrolysis system continues to advance. Molecular simulations and reaction kinetics can predict pyrolysis pathways for different feedstocks, guiding equipment design and process optimization. Integrated pyrolysis systems capable of processing multiple types of waste may achieve higher efficiency in resource recovery and energy utilization.

In conclusion, understanding pyrolysis at the molecular level provides both scientific insight and practical guidance for industrial applications. Structural differences among feedstocks determine product types, energy requirements, and equipment choices. By analyzing molecular-level mechanisms, an optimal balance between environmental and economic benefits can be achieved.